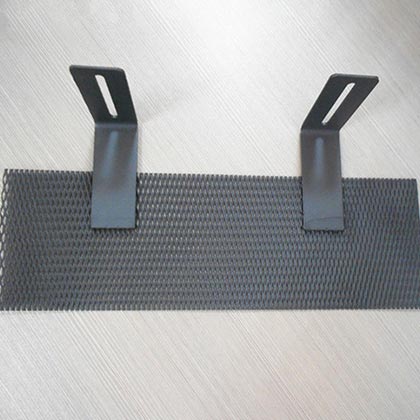

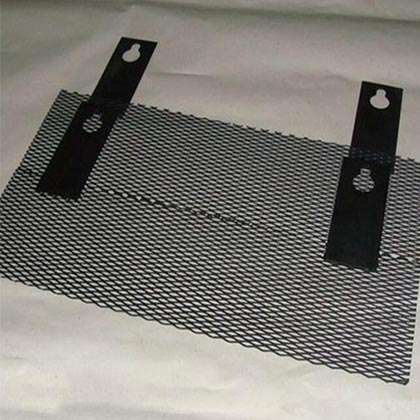

Products description

The iridium oxide coated titanium electrode has excellent catalytic activity in the oxygen evolution reaction, strong stability in acidic solution, extremely high anti-corrosion performance, high current efficiency, long working life, extremely light electrode weight, and can carry a large current density. The medium will not be polluted, and the electrode substrate can be reused. The iridium oxide coated titanium electrode is the most promising coated electrode in the field of oxygen evolution.

Advantages of Iridium Oxide Coated Titanium Electrode

–High anti-corrosion property

–High catalytic property

–High current efficiency property

–Keep the operating voltage stably

–High property of current efficiency& Saving electricity

–High speed of plating

–Long service life

Applications of Iridium Oxide Coated Titanium Electrode

–Electrolytic copper foil,

–Steel galvanizing,

–Cathodic protection,

–Organic electrolytic synthesis,

–Circuit board electroplating,

–Chrome electroplating,

–Swirl electrolysis,

–Hydrometallurgy,

–HHO generator,

–Sewage treatment and other industries