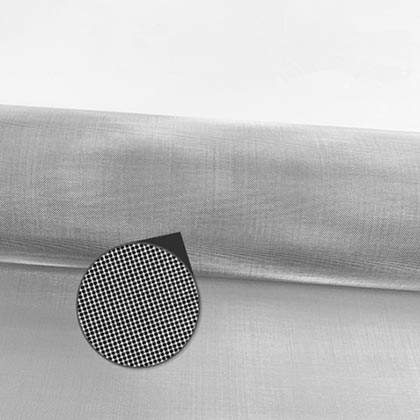

Products description

Monel woven wire mesh a type of woven wire mesh made from nickel-based alloy material. Monel is the alloy of nickel,copper and other chemical elements.According to the different chemical elements, it can be divided in to Monel alloy 400 and monel alloy K500.

Monel 400 has outstanding corrosion resistance property in the flowing sea water.It can also resist to stress corrosion cracking. Alloy 400 is the most widely used monel material. With added aluminum, Monel K500 offers greater tensile strength and hardness than the Monel 400.

Monel Mesh offers excellent resistance to seawater and steam from low to elevated temperatures. Monel Mesh is also resistant to rapidly flowing brackish water, scc, hydrochloric acid and hydrofluoric acid in the deaerated conditions. It is widely used in sea water applications, chemical and hydrocarbon processing systems.

Monel mesh features

Corrosion resistance in the sea water.

Corrosion resistance in the chemical solvent.

Corrosion resistance in the acidoid, such as hydrofluoric acid, phosphoric acid.

Corrosion resistance in the alkaline matter.

Resist to stress corrosion cracking.

High tensile strength.

Excellent hardness.

Long lasting and durable.

|

Specification List of Monel Wire Mesh

|

|

Mesh

|

Wire Dia

mm

|

Mesh

Opening mm

|

Opening Area

%

|

Weight

kg/m2

|

Mesh

|

Wire Dia

mm

|

Mesh Opening

mm

|

Opening Area

%

|

Weight

kg/m2

|

|

8

|

0.70

|

2.47

|

61%

|

2.19

|

30

|

0.25

|

0.596

|

50%

|

1.05

|

|

10

|

0.60

|

1.94

|

58%

|

2.01

|

40

|

0.20

|

0.435

|

47%

|

0.89

|

|

12

|

0.50

|

1.61

|

58%

|

1.68

|

40

|

0.25

|

0.385

|

37%

|

1.40

|

|

14

|

0.50

|

1.31

|

52%

|

1.96

|

60

|

0.15

|

0.273

|

42%

|

0.75

|

|

16

|

0.40

|

1.18

|

56%

|

1.43

|

80

|

0.12

|

0.198

|

39%

|

0.57

|

|

18

|

0.40

|

1.01

|

51%

|

1.61

|

100

|

0.10

|

0.154

|

37%

|

0.50

|

|

20

|

0.40

|

0.87

|

47%

|

1.79

|

120

|

0.08

|

0.131

|

39%

|

0.43

|

|

24

|

0.28

|

0.77

|

54%

|

1.05

|

150

|

0.06

|

0.109

|

42%

|

0.30

|

|

28

|

0.25

|

0.65

|

52%

|

0.98

|

200

|

0.05

|

0.077

|

37%

|

0.28

|