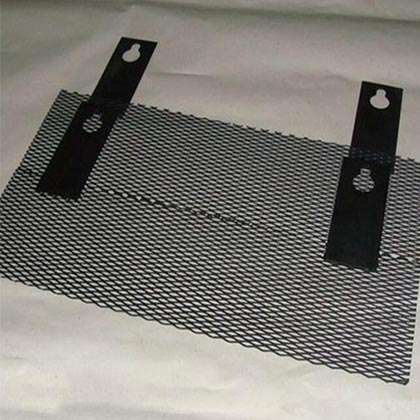

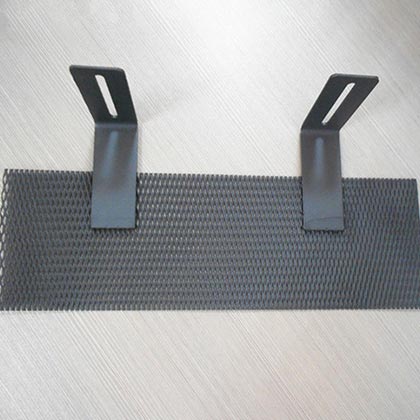

Products description

Ruthenium coated titanium anode consists of the titanium substrate and active coating(RuO2/RuO2-IrO2).The metal substrate plays the role of skeleton and conductivity,while the active coating participates in the electrochemical reaction.

Ruthenium-based titanium electrode is used in chlorine evolution reaction, has extremely low chlorine evolution overpotential, excellent stability and durability, has extremely high anti-corrosion performance,will not pollute the medium. Even after the elecrode loses activity,the substrate will not be affected, can be reused.

Advantages of Ruthenium Coated Anodes

–Good stability and durability( both mechanically and chemically)

–Ruthenium-coated anodes have good electrocatalytic properties and high surface area)

–Ruthenium-coated anodes have high electrical conductivity

–They have minimal trapping of gas bubbles and long working life

–Ruthenium-coated anodes is with low chlorine evolution overpotential

Application of Ruthenium Coated Anodes

-Chlor-alkali industry

-Electrolysis of sodium hypochlorite

-Hydrometallurgy

-Diaphragm method alkali production,

-Electrolysis to produce chlorine dioxide

-Electrolysis of seawater to produce chlorine

-Sewage treatment

-Sterilization and algae killing of circulating water

-Electrolytic metal deposition in chloride system

-Ionized water electrolysis

-Ffruit and vegetable machine disinfection,

-EDI electrodialysis