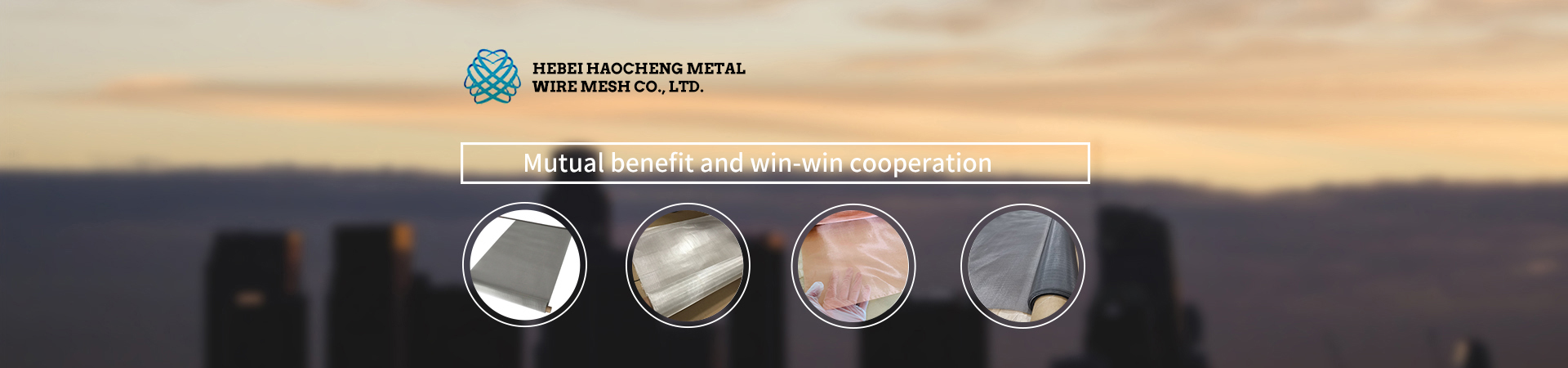

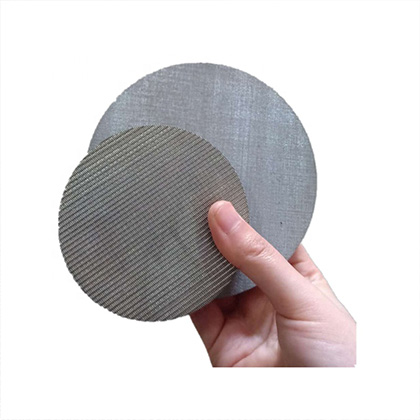

Sintered Wire Mesh is a filtering cloth made by pressing multi-layer woven wire cloth, then sintered together in vacuum furnace. This kind of filtering cloth is much better than common metal woven wire mesh with good strength, hardness and good positioning of opening. Its comprehensive property is superior to sintered metal powder and porcelain.

-Material: SS304, SS304L, SS316, SS316L, SS904L, UNS S31803, UNS S32750, Hastelloy, Monel, Inconel, etc.

-Layers and thickness

5 Layers-1.7mm

6 Layers-3.5mm

(Special specification can be customized)

-Common sheet sizes:

500mm*1000m, 1000mm*1000mm, 600mm*1200mm, 1200mm*1200mm

-Minimum micron size: 1 micron

-Types: sintered flat sheet and sintered tube

Features:

- High strength and good rigidity: It has high mechanical strength and compressive strength, and has good processing, welding and assembly performance and easy to use.

- Uniform and stable accuracy: Uniform filtration performance can be achieved for all filtration precisions, and the mesh does not change during use.

- Wide use environment: It can be used in the temperature environment of -200 °C ~ 600 °C and filtration of acid and alkali environment.

- Excellent cleaning performance: good counter-current cleaning effect, can be used repeatedly, long life (can be washed by countercurrent water, filtrate, ultrasonic, melting, baking, etc.).

Usage:

- Used in high temperature environment as dispersion cooling material

- For gas distribution, fluidized bed orifice material

- For high precision, high reliability high temperature filter materials

- For high pressure backwash oil filter